Federal Motor Vehicle Safety Standards; Fuel System Integrity; Crossover Lines |

|---|

Topics: National Highway Traffic Safety Administration, Federal Motor Vehicle Safety Standards

Topics: National Highway Traffic Safety Administration, Federal Motor Vehicle Safety Standards

|

Barry Felrice

Federal Register

May 17, 1994

[Federal Register: May 17, 1994]

=======================================================================

-----------------------------------------------------------------------

DEPARTMENT OF TRANSPORTATION

National Highway Traffic Safety Administration

49 CFR Part 571

[Docket No. 94-39; Notice 1]

RIN 2127-AC62

Federal Motor Vehicle Safety Standards; Fuel System Integrity;

Crossover Lines

AGENCY: National Highway Traffic Safety Administration (NHTSA), (DOT).

ACTION: Notice of proposed rulemaking (NPRM).

-----------------------------------------------------------------------

SUMMARY: This notice proposes to amend Federal Motor Vehicle Safety

Standard No. 301, Fuel System Integrity, to require vehicles equipped

with a crossover line connecting dual fuel tanks to comply with

requirements that would reduce the likelihood of fuel spillage. The

affected vehicles would be almost exclusively heavy trucks. A vehicle

equipped with a crossover fuel line would not be permitted to have fuel

spillage exceeding 30 grams (1 ounce) (by weight) beginning with the

onset of the application of a 11,100 Newtons (2,500 pounds) test force

and ending two minutes after the end of the test force application. The

agency has tentatively determined that the proposed requirements would

eliminate most of the fuel spillage from crossover line breakage and

prevent a substantial number of fires and secondary crashes due to fuel

spillage.

DATES: Comments. Comments must be received on or before July 18, 1994.

Proposed Effective Date. The proposed amendments in this notice

would become effective [insert date one year after publication of a

final rule in the Federal Register.]

ADDRESSES: Comments should refer to the docket and notice numbers above

and be submitted to: Docket Section, National Highway Traffic Safety

Administration, 400 Seventh Street, SW., Washington, DC 20590. Docket

hours are 9:30 a.m. to 4 p.m., Monday through Friday.

FOR FURTHER INFORMATION CONTACT: Dr. William J.J. Liu, Office of

Vehicle Safety Standards, National Highway Traffic Safety

Administration, 400 Seventh Street, SW., Washington, DC, 20590.

Telephone: (202) 366-2264.

SUPPLEMENTARY INFORMATION:

I. Background

A. Current Federal Motor Vehicle Safety Standard No. 301

B. Federal Motor Carrier Safety Regulations

II. Rulemaking Petition

III. Crossover Lines and Frangible Valves

IV. NHTSA's Initial Analysis of the California Highway Patrol

Petition

A. Grant Notice and Initial Study

B. NHTSA's Test Program

C. Society of Automotive Engineers

V. Agency's Decision to Propose Amending Standard No. 301

A. General Considerations

B. Requirements and Test Procedures

C. Applicability

D. Benefits

E. Costs

F. Leadtime

I. Background

A. Current Federal Motor Vehicle Safety Standard No. 301

Federal Motor Vehicle Safety Standard No. 301, Fuel System

Integrity, specifies requirements for the integrity of the entire motor

vehicle fuel system which includes the fuel tanks, lines and

connections and emission controls. The standard's purpose is to reduce

the deaths and injuries occurring in fires that result from fuel

spillage during and after motor vehicle crashes, and resulting from

ingestion of fuels during siphoning. The standard currently applies to

passenger cars, and to multipurpose passenger vehicles, trucks and

buses that have a gross vehicle weight rating (GVWR) of 10,000 pounds

or less and use fuel with a boiling point above 32 deg. Fahrenheit. The

standard also applies to school buses with a GVWR over 10,000 pounds

that use fuel with a boiling point above 32 deg. F.

Standard No. 301 limits the amount of fuel spillage that can occur

from fuel systems of vehicles both during and after various specified

barrier impact tests. Fuel spillage as a result of any of the required

impact tests cannot exceed one ounce by weight during the time from the

start of the impact until motion of the vehicle has stopped, and cannot

exceed a total of five ounces by weight in the five-minute period

following cessation of motion. For the remaining portion of the test

period, fuel spillage cannot exceed one ounce by weight during any one-

minute interval. Similar fuel spillage limits are required for the

standard's static rollover test.

The impact tests specified for all vehicles that have a GVWR of

10,000 pounds or less are a 30-mph frontal fixed barrier impact, a 30-

mph rear moving barrier impact, and a 20-mph lateral moving flat

barrier impact. A static rollover test is conducted following the

barrier impacts.

Only one impact test is specified for heavy school buses, i.e.,

those with a GVWR over 10,000 pounds. It is a 30-mph moving contoured

barrier crash test at any point and any angle. A static rollover test

is not specified for heavy school buses.

B. Federal Motor Carrier Safety Regulations

The Federal Highway Administration (FHWA) requires commercial motor

vehicles engaged in interstate commerce to comply with its Federal

Motor Carrier Safety Regulations (FMCSRs). Among the FMCSRs'

requirements in Subpart E for Fuel Systems are ones addressing fuel

lines (Sec. 393.65(f)) and fuel line valves (Sec. 393.65(g)). Section

393.65(f), Fuel Lines, states that a fuel line which is not completely

enclosed in a protective housing must not extend more than two inches

below the fuel tank or its sump. Diesel fuel crossover, return, and

withdrawal lines which extend below the bottom of the tank or sump must

be protected against damage from impact.\1\ Under this provision, every

fuel line must be (1) long enough and flexible enough to accommodate

normal movements of the parts to which it is attached without incurring

damage and (2) secured against chafing, kinking, or other causes of

mechanical damage. Section 393.65(f), Excess flow valve, states that

when pressure devices are used to force fuel from a fuel tank, a

device, which prevents the flow of fuel from the fuel tank if the fuel

feed line is broken, must be installed in the fuel system.

---------------------------------------------------------------------------

\1\A crossover line is a flexible hose connected between two

vehicle fuel tanks at or near the bottom of the tanks.

---------------------------------------------------------------------------

II. Rulemaking Petition

On May 30, 1986, the California Highway Patrol (CHP) submitted a

rulemaking petition to NHTSA to amend Standard No. 301 to apply to

medium and heavy trucks and truck tractors, i.e., those that have a

GVWR greater than 10,000 pounds.\2\ The petition requested NHTSA to add

performance requirements to reduce the frequency and magnitude of fuel

spills caused when road debris damage the fuel tank, the shut-off

valve, or the crossover line on medium and heavy trucks and truck

tractors.

---------------------------------------------------------------------------

\2\These vehicles are referred to as ``heavy trucks'' throughout

the remainder of the notice.

---------------------------------------------------------------------------

The CHP based its petition on data gathered from 142 diesel fuel

spills that occurred on Southern California highways during 1984 and

1985. According to the petition, ``one-third of the 142 spills were

caused by an object on the road being struck by [a heavy vehicle's]

front wheels and thrown against the tank or fuel lines.'' CHP stated

that the major consequence of these diesel fuel spills was the cost to

the State of cleaning the spill, investigating the leak, and

undertaking traffic control. In addition, CHP stated that seven

``secondary'' accidents were caused by vehicles that struck a dropped

fuel tank or skidded out-of- control on spilled fuel. Based on the

above considerations, CHP requested that NHTSA issue standards that

would protect fuel lines, crossover lines and bottom fittings against

breakage from road debris.

III. Crossover Lines and Frangible Valves

By gravitational effect, a crossover line enables both fuel tanks

to maintain a constant fuel level and allows the engine to draw fuel

from only one tank. On vehicles equipped with dual tanks, the crossover

line is typically one of the fuel system components close to the

ground. In this location, unprotected crossover lines are susceptible

to being struck by road debris, or being snagged in crashes when the

truck overrides another vehicle or highway structure.

Given this potential danger, vehicle manufacturers may protect

crossover lines from contact with road debris by routing the fuel line

through a metal sleeve or attaching the fuel line to the rear of an

angle iron or beam. Nevertheless, this manner of protection at times is

not capable of preventing crossover line failures when a truck

overrides another vehicle or highway structure.

Another way to protect crossover lines is through the use of

breakaway/frangible valves which stop fuel flow if the crossover line

fails.\3\ Such devices are installed at the point where the line would

otherwise be attached to each tank. They serve as the weakest point in

the line, so that they break before any other part of the line fails.

When the frangible valve breaks, it seals both sides of the break, thus

stopping the fuel flow before fuel can be spilled. To date, relatively

few motor vehicles have been equipped with these devices.

---------------------------------------------------------------------------

\3\These valves are referred to as frangible valves throughout

the remainder of the document.

---------------------------------------------------------------------------

IV. NHTSA's Initial Analysis of the California Highway Patrol Petition

A. Grant Notice and Initial Study

On May 2, 1988, NHTSA published a notice granting the CHP petition

that requested Standard No. 301 be amended to establish minimum

positioning, size, and strength requirements to protect fuel lines,

crossover lines and bottom fittings against breakage when struck by

road debris. (53 FR 15578). In the grant notice, the agency stated that

The issues raised by the petitioner warrant further

consideration. NHTSA plans to conduct research into the issue of

heavy vehicle post-crash fires to determine whether rulemaking is

appropriate on this issue.

In September 1989, NHTSA published a final report titled, ``Heavy

Truck Fuel System Safety Study--Prepared in Response to Senate Report

No. 100-198 HR 2890 Department of Transportation and Related Agencies

Appropriation Act of 1988,'' based on a research study prepared by the

University of Maryland's Fire Protection Engineering Department.\4\ The

report analyzed and discussed accident records for truck fuel system

fires, diesel fuel system designs, chemistry and physics of truck

fires, system safety analyses, and fire mitigation strategies. With

respect to the CHP petition, the report found that spilled diesel fuel

is difficult to ignite, except during crashes when the fuel may be

misted or vaporized. The report concluded that in some instances, fires

originate from diesel fuel spilled from breached fuel system

components, and improvements to the fuel system to prevent breaching

may be possible. In addition, the report indicated that significant

benefits could be obtained by improving the protection of crossover

lines.

---------------------------------------------------------------------------

\4\(DOT HS-807-484, September 1989).

---------------------------------------------------------------------------

B. NHTSA's Test Program

NHTSA's Vehicle Research and Test Center (VRTC) prepared a report

titled, ``Testing to Develop Fuel System Integrity Standard,'' March

1992, based on a test program evaluating crossover lines. A copy of

this report has been placed in the docket. The purpose of the test

program was to develop a test procedure that could be used in a

performance standard to ensure crossover line integrity. VRTC employed

a quasi-static pull test in which force was applied at a constant

displacement rate to crossover lines to evaluate crossover line

protection. While such a test is not an exact replication of conditions

in which road debris strike a crossover line, it provides an acceptable

approximation of that situation. Further, it provides an easily

duplicated and repeatable method of evaluation.

The VRTC study found that a shear force of between 100 and 600

pounds is necessary to sever frangible valves while a shear force

between 700 and 1,000 pounds is necessary to sever an unprotected fuel

line. The study also found that devices called ``substantial protection

devices'' protect crossover fuel lines even when a shear force of

11,100 Newtons (2,500 pounds) is applied. The basis for the 11,000

Newtons (2,500 pounds) is discussed in a subsequent section of the

notice titled ``Requirements and Test Procedures.'' ``Substantial

protection devices'' are used as a brace loaded in compression to

reduce the amount of flexing of the frame and the tank mounting

brackets. They are typically metal frames in which the crossover lines

are placed. They are typically bolted to the tank mounting brackets,

with the brackets providing longitudinal support. In contrast, testing

of ``non-substantial protection devices'' indicated that they offer

little additional protection for the crossover line. This type of

protection device is typically light weight and is bolted to the frame

rails.

VRTC concluded that a potentially appropriate test procedure would

be one specifying the application of a specified force to the crossover

line protection device. That procedure could be coupled with a

requirement limiting the maximum amount of fuel leakage that would be

allowed during the force application and for a period of time

thereafter.

C. Society of Automotive Engineers.

NHTSA notes that the Society of Automotive Engineers (SAE) is

currently drafting a Recommend Practice, J1624, Fuel Crossover Line, to

evaluate crossover lines and set minimum strength requirements for

these devices. This Recommended Practice would set forth tests

procedures and requirements related to crossover lines. The SAE draft

Recommended Practice includes a different test procedure than the one

being proposed by NHTSA. The Recommended Practice specifies a different

and higher load level (22,200 Newtons (5,000 pounds) compared to 11,100

Newtons (2,500 pounds)), and the load is applied in a different manner.

In addition, the Recommended Practice requires the removal of the

vehicle's transmission, an action the agency disfavors. NHTSA requests

comments on the differences between these procedures and their effect

on benefits and costs.

V. Agency's Decision to Propose Amending Standard No. 301

A. General Considerations

Based on the foregoing and other available information, NHTSA has

decided to propose amending Standard No. 301 to limit fuel spillage

experienced by vehicles equipped with a crossover fuel line to 30 grams

(1 ounce) (by weight) beginning with the onset of the application of a

11,100 Newtons (2,500 pounds) test force and ending two minutes after

the end of the test force application.

The agency envisions two primary methods by which a vehicle

manufacturer could comply with the proposed requirements. One would be

the installation of a ``substantial protection device.'' The other

would be the installation of a frangible valve.

The agency has tentatively determined that the proposed

requirements would eliminate most of the fuel spillage from crossover

line breakage and annually prevent one fatality and 55 injuries that

occur in secondary crashes due to fuel spillage. A detailed analysis of

the rulemaking's anticipated benefits is presented in the Preliminary

Regulatory Evaluation (PRE), which has been placed in the public

docket.

NHTSA requests comments on the proposal, including whether there is

a safety need for it. Would the installation of a substantial crossover

line protection device or frangible valves on a crossover line prevent

fuel spillage from damaged crossover lines due to impacts by highway

debris or other crashes? To what extent are other components in the

fuel system (e.g., supply and return lines, water separators, fuel

heaters) vulnerable to damage from road debris?

B. Requirements and Test Procedures

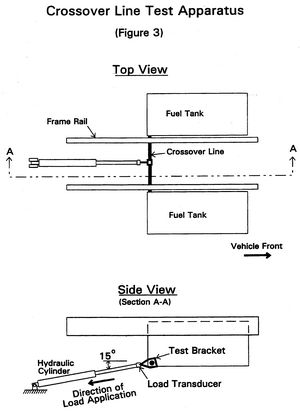

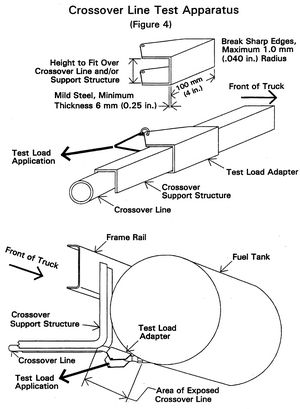

NHTSA is proposing several details related to the crossover line

requirement and test procedures. These include the permissible amount

of fuel spillage, the appropriate maximum test load, the time for

evaluating fuel spillage, the nature of force application, the point

and angle of force application, and the nature of the test apparatus.

As explained above, each vehicle that is equipped with a crossover

line connecting dual fuel tanks would be permitted to have only a

limited amount of fuel spillage after the application of a test force.

The proposed requirement would permit fuel spillage of 30 grams (1

ounce) by weight. This amount of fuel spillage is based on the VRTC

report of crossover lines that indicated that no frangible valve is

capable of stopping the fluid flow instantaneously. It is also based on

previous agency rulemakings about fuel system integrity. For instance,

the static rollover test in Standard No. 301 permits fuel spillage of

30 grams (1 ounce) per minute after each 90 deg. rotation. (See S6.4)

The agency invites comments about whether to permit fuel spillage in

addition to 30 grams of fuel.

NHTSA is proposing to specify that a test force of 11,100 Newtons

(2,500 pounds) be applied to any crossover fuel line connecting dual

fuel tanks. This test force is based on the tests run by VRTC. These

tests indicated that a force application of 11,100 Newtons (2,500

pounds) would be sufficient to require the installation of devices that

would protect the crossover lines while screening out less protective

devices. The agency invites comments on whether the proposed test load

is appropriate to ensure crossover line integrity. Would the agency's

specification of a shear force less than 11,100 Newtons (2,500 pounds)

result in a significant increase in the number of severed fuel lines

compared to the number that would occur if a shear force of 11,100

Newtons (2,500 pounds) were specified? If so, how much of an increase

would be expected? How often do vehicles equipped with a crossover line

contact road debris but not leak? Conversely, would it be more

appropriate to specify a higher test force?

The proposed time period for evaluating the fuel spillage from the

crossover line begins with the onset of the application of the test

force and ends two minutes after the end of the test force application.

The agency tentatively concludes that a two minute period is sufficient

to evaluate a crossover fuel line failure. The agency requests comments

on whether the proposed two minute period is appropriate to ensure

crossover fuel line integrity.

NHTSA is proposing to specify that the test force be applied to the

full level between 10 and 20 seconds, be maintained between 5 and 10

seconds, and then be released. This time frame is based on the VRTC

tests. The agency considered an alternative approach in which the load

would have been applied at a rate of 1.9 cm/second. However, the agency

has tentatively concluded that the apply-hold-release time provision is

consistent with practical laboratory procedures. NHTSA requests

comments about how the force application should be specified.

NHTSA is proposing to specify that the test force be applied

downward in a vertical plane and toward the rear of the vehicle,

parallel to the longitudinal axis of the vehicle, and at an angle of

15 deg. with the road surface. This test condition is based on VRTC's

recommendation that the pull test be conducted at a 15 deg. angle

relative to the road. The agency notes that in real-world situations in

which road debris contact the vehicle, the dynamic load would be

applied at various angles. Nevertheless, the general direction is

toward the rear of the vehicle. The tests at VRTC indicated that the

small variations in test angle between 0 deg. and 15 deg. did not

significantly affect the test results. The agency believes that this

test angle would simplify the test set- up, thereby making it more

practicable.

NHTSA is also proposing specific provisions related to the test

apparatus, a hydraulic device whose characteristics are described in

Figures 3 and 4. The test apparatus incorporates a loading application

device attached to the end of a hydraulic pulling device which pulls

the crossover line structure. The test loading application device has a

length of four inches which would be placed around the crossover line

or support structure. This would enable testing the exposed ends of a

crossover line near the juncture at the fuel tank if the exposed area

exceeded four inches in length. An additional allowance of two inches

is provided since the test load application device may not fit over

curved portions of a crossover support structure at its transition from

horizontal to vertical. Exposed portions of crossover lines would have

to be tested if the exposed length of crossover line exceeds six

inches. NHTSA requests comments about the proposed test conditions as

well as alternative procedures such as the SAE Recommended Practice

J1624.

C. Applicability

Standard No. 301 currently applies to vehicles with a GVWR of

10,000 pounds or less and to heavy school buses. This notice proposes

to extend Standard No. 301's applicability to any vehicle that is

equipped with a crossover line that connects dual fuel tanks. As a

practical matter, the proposed amendment would affect heavy trucks

almost exclusively. A majority of these vehicles are equipped with a

crossover line that connects dual fuel tanks. In contrast, light

vehicles typically are not equipped with dual fuel tanks equipped with

a crossover line. Nevertheless, even though the proposal would not

affect light vehicles, the agency is proposing to apply the

requirements to any vehicle equipped with a crossover line that

connects dual tanks in case light vehicles are equipped with such

devices in the future.

The proposed requirements would affect a vehicle only if it is

equipped with a crossover line connecting dual fuel tanks. The proposal

would not require a vehicle to be equipped with crossover lines.

Further, the proposal would not prevent vehicles equipped with dual

fuel tanks from being equipped with devices other than crossover lines

for filling up both fuel tanks (e.g., dual fuel supply and returns

system). The agency does not wish to hinder the efforts of

manufacturers which are developing devices that may eliminate the need

for crossover lines. The agency requests comments about the

applicability of the proposed crossover line integrity requirements.

D. Benefits

NHTSA anticipates that, if adopted, the proposed amendment to

Standard No. 301 would significantly reduce the potential involvement

of heavy truck crossover lines in fatal and injury-producing accidents.

As a result of the amendment, there would be fewer breached fuel lines

and less fuel spilled by heavy trucks. The PRE estimates that the

rulemaking would prevent one fatality and two injuries each year

resulting from crossover line breaches in crashes involving truck

undercarriages. In addition, the rule would prevent one fatality and 55

injuries that occur in secondary crashes. NHTSA also estimates that

about 131,000 gallons of fuel are spilled each year from crossover

lines that are breached. The annual direct economic costs associated

with this fuel spillage are estimated to be $8,423,000 per year. These

costs are broken down as follows: Fuel spill cleanup costs of

$2,181,000, traffic delays of 221,000 vehicle-hours costing $2,393,000

in lost productivity, environmental damage of $3,425,000 from

unreported fuel spills that are not properly cleaned-up, vehicle

property damage of $276,000, and fuel spillage loss of $148,000. While

no studies have been conducted to estimate an effectiveness rate for

the proposed requirement, i.e., the degree to which it would prevent

these losses, the agency expects that a high percentage of the fuel

spillage incidents and the associated costs would be prevented, since

most of the frangible valves now on the market appear to be able to

prevent fuel spillage.

NHTSA requests comments about the anticipated benefits of the

proposal to reduce fuel spillage in vehicles with crossover lines.

Please provide any information on frangible valve performance in over-

the-road usage.

E. Costs

Among the PRE's principal conclusions are that vehicle

manufacturers could comply with the proposed performance requirements

and thus eliminate crossover fuel line spills by either installing

frangible valves, or by providing a crossover line protection device.

NHTSA is basing the following estimate on the alternative to install

frangible valves since they appear to provide more protection against

spills at a lower cost. The vehicle manufacturers' choice of frangible

valves would minimize the rulemaking's overall costs. These valves are

currently commercially available for a valve manufacturer's estimated

retail cost of $25 per valve including installation. However, based on

agency discussions with valve manufacturers, the cost could be as low

as $15 per valve installed, if sufficient quantities are purchased at a

wholesale rate. This would result in a cost of between $30 and $50 per

vehicle to equip both sides of the crossover line with frangible

valves, since two valves are needed. Given this range of between $30

and $50 per vehicle, the agency has decided to use an average cost of

$40 per vehicle in the PRE. The agency requests comments about whether

this estimate accurately represents the costs related to preventing

fuel spillage caused by severed crossover lines.

NHTSA estimates that the costs associated with installing ``more

substantial'' crossover protection structures rather than ``less

substantial'' structures'' to be $50 to $60 per vehicle. This includes

the extra cost of steel structural components and labor to manufacture

the structure. In addition, ``more substantial'' structures would

result in a weight premium of an estimated 20 pounds. Because of this

weight penalty and the higher estimated cost, NHTSA believes that most

vehicle manufacturers and operators would use frangible valves.

NHTSA notes that eliminating the crossover line by installing dual

supply and return lines on trucks is an alternative to increasing the

strength of the crossover line structure or installing frangible

valves. Although the agency has not determined the precise cost of dual

supply and return systems, it believes that their cost would be higher

than either frangible valves or substantial crossover support

structures. The agency requests data about the number of vehicles using

dual supply and return systems versus vehicles using crossover lines.

According to the Motor Vehicle Manufacturers Association

publication, ``1992 Facts & Figures,'' there were 70,831 medium and

171,309 heavy new trucks sold in the United States in 1991. The agency

estimates that about 20 percent of medium trucks and 70 percent of

heavy trucks are equipped with dual fuel tanks, based on information

provided by truck manufacturers. Based on these figures, 14,166 medium

and 119,916 heavy new trucks were equipped with crossover lines in

1991. Based on those figures, the annual cost to install frangible

valves on these vehicles at a cost of $40 per vehicle would be as

follows:

Medium Trucks--$567,000

Heavy Trucks--$4,797,000

Total Cost--$5,364,000

NHTSA requests comments about the current production levels of

vehicles equipped with crossover lines. What number and percentage of

heavy, medium, and light trucks are equipped with dual fuel tanks? By

vehicle size, what number and percentage of dual fuel tanks are

equipped with a crossover line? For dual fuel tanks that are not

equipped with a crossover line, what method of fuel level equalization

is used? By vehicle size, what number and percentage of dual fuel tanks

are equipped with alternative fuel equalization devices? Is there a

trend for vehicles with dual fuel tanks to be equipped with dual feed

and return lines for drawing fuel from both fuel tanks?

NHTSA also requests comments about the current production levels of

vehicles equipped with devices used to prevent or reduce the number of

crossover line breaches. What number and percentage of vehicles

equipped with crossover lines are equipped with (1) crossover line

protection devices that would meet the proposed strength requirements,

(2) frangible valves, or (3) any other technologies that would enable a

vehicle to comply with the proposed requirements?

NHTSA anticipates that the compliance test costs incurred by

vehicle manufacturers would not be significant because it believes that

most manufacturers would meet the proposed requirements by installing

frangible valves instead of providing crossover protection devices. The

agency estimates that most of the cost associated with conducting the

proposed compliance test would be about $400 to $1000, with the cost

range of $400 for a manufacturer with in-house equipment and capability

to $1,000 for a manufacturer using an outside laboratory. The agency

requests comments about the cost of compliance testing of the proposed

requirements.

F. Leadtime

NHTSA anticipates that truck manufacturers would need to devote

relatively minor engineering and development time to incorporate

frangible valves or crossover line protection devices in their current

vehicle designs. Frangible valves are readily available. The agency

expects that valve manufacturers could increase production to meet the

additional demand for such valves. Since the agency does not anticipate

any significant leadtime problems, it is proposing that the amendment

take effect one year after the final rule's publication in the Federal

Register. The agency welcomes comments about whether such a leadtime is

appropriate.

Rulemaking Analyses and Notices

Executive Order 12866 and DOT Regulatory Policies and Procedures

This notice was not reviewed under E.O. 12866. NHTSA has analyzed

this proposal and determined that it is not ``significant'' within the

meaning of the Department of Transportation's regulatory policies and

procedures. A PRE setting forth the agency's detailed analysis of the

economic effects of this proposal has been prepared and been placed in

the docket. A summary of the anticipated benefits and costs appears

above.

Regulatory Flexibility Act

In accordance with the Regulatory Flexibility Act, NHTSA has

evaluated the effects of this action on small entities. Based upon this

evaluation, I certify that the proposed amendments would not have a

significant economic impact on a substantial number of small entities.

This action would primarily affect the manufacturers of heavy trucks

and frangible valves. The agency is not aware of any manufacturer of

heavy vehicles or frangible valves that would be considered a small

entity. The agency does expect that the requirements would increase the

market for and production of such valves. The added cost of modifying a

vehicle to comply with the proposed requirements is very small in

comparison to the overall cost of a vehicle. Therefore, these changes

would not significantly affect purchase decisions. The industry test

cost per vehicle to assure compliance with the proposal would be even

smaller in comparison to the vehicle's overall price. For these

reasons, vehicle manufacturers, small businesses, small organizations,

and small governmental units which purchase motor vehicles would not be

significantly affected by the proposed requirements. Accordingly, no

regulatory flexibility analysis has been prepared.

Executive Order 12612 (Federalism)

This agency has analyzed this action in accordance with the

principles and criteria contained in E.O. 12612 and has determined that

the proposed rule would not have sufficient Federalism implications to

warrant preparation of a Federalism Assessment. No State laws would be

affected.

National Environmental Policy Act

The agency has considered the environmental implications of this

proposed rule in accordance with the National Environmental Policy Act

of 1969 and has determined that the proposed rule would improve the

human environment by eliminating spillage of approximately 131,000

gallons of fuel each year.

Civil Justice Reform

This proposed rule would not have any retroactive effect. Under

section 103(d) of the National Traffic and Motor Vehicle Safety Act

(Safety Act; 15 U.S.C. 1392(d)), whenever a Federal motor vehicle

safety standard is in effect, a state may not adopt or maintain a

safety standard applicable to the same aspect of performance which is

not identical to the Federal standard, except to the extent that the

state requirement imposes a higher level of performance and applies

only to vehicles procured for the State's use. Section 105 of the

Safety Act (15 U.S.C. 1394) sets forth a procedure for judicial review

of final rules establishing, amending or revoking Federal motor vehicle

safety standards. That section does not require submission of a

petition for reconsideration or other administrative proceedings before

parties may file suit in court.

Public Comments

Interested persons are invited to submit comments on the proposal.

It is requested but not required that 10 copies be submitted.

All comments must not exceed 15 pages in length. (49 CFR 553.21).

Necessary attachments may be appended to these submissions without

regard to the 15-page limit. This limitation is intended to encourage

commenters to detail their primary arguments in a concise fashion.

If a commenter wishes to submit certain information under a claim

of confidentiality, three copies of the complete submission, including

purportedly confidential business information, should be submitted to

the Chief Counsel, NHTSA, at the street address given above, and seven

copies from which the purportedly confidential information has been

deleted should be submitted to the Docket Section. A request for

confidentiality should be accompanied by a cover letter setting forth

the information specified in the agency's confidential business

information regulation. 49 CFR part 512.

All comments received before the close of business on the comment

closing date indicated above for the proposal will be considered, and

will be available for examination in the docket at the above address

both before and after that date. To the extent possible, comments filed

after the closing date will also be considered. Comments received too

late for consideration in regard to the final rule will be considered

as suggestions for further rulemaking action. The NHTSA will continue

to file relevant information as it becomes available in the docket

after the closing date, and it is recommended that interested persons

continue to examine the docket for new material.

Those persons desiring to be notified upon receipt of their

comments in the rules docket should enclose a self-addressed, stamped

postcard in the envelope with their comments. Upon receiving the

comments, the docket supervisor will return the postcard by mail.

List of Subjects in 49 CFR part 571

Imports, Motor vehicle safety, Motor vehicles, Rubber and rubber

products, Tires.

In consideration of the foregoing, the agency proposes to amend 49

CFR 571.301, Fuel System Integrity, to read as follows:

PART 571-- FEDERAL MOTOR VEHICLE SAFETY STANDARDS

1. The authority citation for part 571 would continue to read as

follows:

Authority: 15 U.S.C. 1392, 1401, 1403, 1407; delegation of

authority at 49 CFR 1.50.

2. Section 571.301 would be amended by revising S3, S5, S6 and the

introductory text of S7 to read as follows and by adding a definition

of ``crossover line'' to S4 to be placed in the proper alphabetical

location and by adding S7.6 through S7.6.3 to read as follows:

Sec. 571.301 Standard No. 301, Fuel System Integrity.

* * * * *

S3. Application. This standard applies to passenger cars, and to

multipurpose passenger vehicles, trucks and buses that have a GVWR of

10,000 pounds or less and use fuel with a boiling point above 32 deg.

F, and to school buses that have a GVWR greater than 10,000 pounds and

use fuel with a boiling point above 32 deg. F. In addition, S5.8

applies to each vehicle that is equipped with a crossover line

connecting dual fuel tanks and uses fuel with a boiling point above

32 deg. F.

S4. Definitions.

* * * * *

``Crossover line'' means a flexible hose connected between two fuel

tanks at or near the bottom of the fuel tanks.

* * * * *

S5. General requirements.

S5.1 Passenger cars, and multipurpose passenger vehicles, trucks,

and buses with a GVWR of 10,000 pounds or less. Each passenger car and

each multipurpose passenger vehicle, truck, and bus with a GVWR of

10,000 pounds or less shall meet the requirements of S6.1 through S6.4.

Each of these types of vehicles that is manufactured to use alcohol

fuels shall also meet the requirements of S6.6. Each vehicle that is

equipped with a crossover line connecting dual fuel tanks shall also

meet the requirements of S6.7.

S5.2 [Reserved]

S5.3 Vehicles (Other than Schoolbuses) with a GVWR greater than

10,000 pounds. Each vehicle (other than a schoolbus) with a GVWR

greater than 10,000 pounds that is equipped with a crossover line

connecting dual fuel tanks shall meet the requirements of S6.7.

S5.4 Schoolbuses with a GVWR greater than 10,000 pounds. Each

schoolbus with a GVWR greater than 10,000 pounds shall meet the

requirements of S6.5. Each schoolbus with a GVWR greater than 10,000

pounds that is manufactured to use alcohol fuels shall meet the

requirements of S6.6. Each schoolbus with a GVWR greater than 10,000

pounds that is equipped with a crossover line connecting dual fuel

tanks shall meet the requirements of S6.7.

S5.5 Fuel spillage: Barrier crash. Fuel spillage for each vehicle

in any fixed or moving barrier crash test shall not exceed 1 ounce by

weight from impact until motion of the vehicle has ceased, and shall

not exceed a total of 5 ounces by weight in the 5-minute period

following cessation of motion. For the subsequent 25-minute period,

fuel spillage during any 1-minute interval shall not exceed 1 ounce by

weight.

S5.6 Fuel spillage: Rollover. Fuel spillage for each vehicle in

any rollover test, from onset of rotational motion shall not exceed a

total of 5 ounces by weight for the first 5 minutes of testing at each

successive 90 deg. increment. For the remaining testing period, at each

increment of 90 deg., fuel spillage during any 1-minute interval shall

not exceed 1 ounce by weight.

S5.7 Alcohol fuel vehicles. Each vehicle manufactured to operate

on an alcohol fuel (e.g., methanol, ethanol) or a fuel blend containing

at least 20 percent alcohol fuel shall meet the requirements of S6.6.

S5.8 Fuel spillage: Crossover line. Fuel spillage for each vehicle

that is equipped with a crossover line connecting two fuel tanks shall

not exceed 30 grams (1 ounce) by weight of fuel in the two-minute

period following the end of the test force application.

S6. Test Requirements.

(a) Each vehicle with a GVWR of 10,000 pounds or less shall meet

the requirements of any applicable barrier crash test followed by a

static rollover, without alteration of the vehicle during test

sequence. A particular vehicle need not meet further requirements after

having been subjected to a single barrier crash test and a static

rollover test. In addition, each vehicle that is equipped with a

crossover line connecting two fuel tanks shall meet the crossover line

test set forth in S6.7.

(b) Each vehicle with a GVWR greater than 10,000 pounds that is

equipped with a crossover line connecting two fuel tanks shall meet the

crossover line test set forth in S6.7.

S6.1 Frontal barrier crash. When the vehicle traveling

longitudinally forward at any speed up to and including 30 mph impacts

a fixed collision barrier that is perpendicular to the line of travel

of the vehicle, or at any angle up to 30 deg. in either direction from

the perpendicular to the line of travel of the vehicle, with 50th

percentile test dummies as specified in part 572 of this chapter at

each front outboard designated seating position and at any other

position whose protection system is required to be tested by a dummy

under the provisions of Standard No. 208, under the applicable

conditions of S7., fuel spillage shall not exceed the limits of S5.5.

S6.2 Rear moving barrier crash. When the vehicle is impacted from

the rear by a barrier moving at 30 mph, with test dummies as specified

in part 572 of this chapter at each front outboard designated seating

position, under the applicable conditions of S5.7, fuel spillage shall

not exceed the limits of S5.5.

S6.3 Lateral moving barrier crash. When the vehicle is impacted

laterally on either side by a barrier moving at 20 mph with 50th-

percentile test dummies as specified in part 572 of this chapter at

positions required for testing to Standard No. 208, under the

applicable conditions of S5.7, fuel spillage shall not exceed the

limits of S5.5.

S6.4 Static rollover. When the vehicle is rotated on its

longitudinal axis to each successive increment of 90 deg. following an

impact crash of S6.1, S6.2, or S6.3, fuel spillage shall not exceed the

limits of S5.6.

S6.5 Moving contoured barrier crash. When the moving contoured

barrier assembly traveling longitudinally forward at any speed up to

and including 30 mph impacts the test vehicle (schoolbus with a GVWR

exceeding 10,000 pounds) at any point and angle, under the applicable

conditions of S7.1 and S7.5, fuel spillage shall not exceed the limits

of S5.5.

S6.6 Anti-siphoning test for alcohol fuel vehicles. Each vehicle

shall have means that prevent a hose made of vinyl plastic or rubber,

with a length of not less than 120 centimeters (cm) (47.2 inches) and

an outside diameter of not more than 5.2 millimeters (mm) (0.20

inches), from contacting the level surface of the liquid fuel in the

vehicle's fuel tank or fuel system, when the hose is inserted into the

filler neck attached to the fuel tank with the fuel tank filled to any

level from 90 to 95 percent of capacity.

S6.7 Crossover fuel lines. When the crossover fuel line test

apparatus is applied to the test vehicle at any point along the

crossover fuel line (including the contiguous protective structure)

with a force of 11,100 Newtons (2,500 pounds), under the applicable

conditions of S7.1 and S7.6, fuel spillage shall not exceed the limits

of S5.8.

S7 Test conditions. The requirements of S5.1, S5.3, S5.4, S5.5 and

S5.6 and S6.1, S6.2., S6.3, S6.4, and S6.5 shall be met under the

following conditions. The requirements of S5.8 and S6.7 shall be met

under the conditions set forth in S7.1.1, S7.1.2, S7.1.5, and S7.6.

Where a range is specified, the vehicle shall be capable of meeting the

requirements at all points within the range.

* * * * *

S7.6 Crossover line test conditions. Compliance with S5.8 and S6.7

shall be demonstrated in accordance with the following:

S7.6.1 Place and level the test vehicle on a rigid surface so that

it is entirely supported by means of the vehicle frame. Secure the test

vehicle so as to prevent any motion of the test load.

S7.6.2 Apply the test force specified in S6.7, as shown in Figures

3 and 4, in a downward direction in a vertical plane toward the rear of

the vehicle direction, and parallel to the vehicle's longitudinal axis,

at an angle of 15 deg. with respect to the road surface.

S7.6.3 Load the crossover line to the 11,100 Newtons (2,500

pounds) in not less than 10 seconds or more than 20 seconds and

maintain it for not less than 5 or more than 10 seconds. Release the

test force in not less than 5 or more than 10 seconds.

S7.6.4 Apply the test force until either 11,100 Newtons (2,500

pounds) is reached, or the crossover line is severed, or total

separation of any of the crossover line valves occurs.

S7.6.5 Ensure that the fuel supply and return lines remain in

place for the testing if they are located on the crossover line.

Sec. 571.301 [Amended]

3. Section 571.301 would be amended by adding Figure 3 and Figure 4

to read as follows:

BILLING CODE 4510-59-P

BILLING CODE 4910-59-C

Issued on: May 11, 1994.

Barry Felrice,

Associate Administrator for Rulemaking.

[FR Doc. 94-11920 Filed 5-16-94; 8:45 am]

BILLING CODE 4910-59-P

BILLING CODE 4910-59-C

Issued on: May 11, 1994.

Barry Felrice,

Associate Administrator for Rulemaking.

[FR Doc. 94-11920 Filed 5-16-94; 8:45 am]

BILLING CODE 4910-59-P